What's The Deal With The Industrial Revolution

The Industrial Revolution is the most important event in economic history, and naturally it gets a lot of attention. While James Watt’s steam engine, invented in 1776, was by far the most important invention of this era, there was an explosion of technology both before and after Watt’s engine that together transformed the world more profoundly than anything since the adoption of agriculture. Few questions are more important than why and how all this happened.

I see a lot of people make arguments like “The Romans didn’t get an Industrial Revolution because they had the wrong kind of coal” or “The Chinese didn’t get an Industrial Revolution because they weren’t capitalist” or “patent laws were the reason that the British started the Industrial Revolution”. This type of answer seems too narrow.

I don’t think there was one reason why the Industrial Revolution happened when and where it did. In my research, it looks like there’s a bunch of critical components. If a civilization is missing even one of them, then it won’t industrialize. A car is a fragile and complex machine, and if one of its many critical parts is missing, then the car won’t run, even if the remaining parts are working perfectly. The Industrial Revolution was much the same.

So far I’ve identified four or five of these rare, critical components. There are likely more which I’m not yet aware of.1

Let’s look at four civilizations which often get brought up in these discussions: the Greek city-states around the time of Archimedes; the Roman empire at its height; Imperial China at its most innovative around the Song Dynasty; and Georgian England where the actual Industrial Revolution occurred.

Tooling. As anyone knows who’s worked anywhere near manufacturing, the hard part of engineering isn’t imagining principles for how a machine could work, it’s designing a configuration which works durably and is practical to build. This depends mostly on what tools you have available to build it with. If you have all the blueprints for a cell phone and all the raw materials, but can only use tools invented before 1900, then you won’t be able to make a cell phone. If you have Iron Age tools, you won’t be able to make a modern pair of pants even if you have the patterns. Tools for cheap and precise manufacturing have improved tremendously over the millennia.

If you read about historical manufacturing and industry, you can get a feel for the constraints they were working under. Some good, short books are Ffoulkes’ The Gun-Founders of England and Moritz’s Grain-Mills and Flour in Classical Antiquity. After enough anecdotes of engineers trying crazy shit like making a cannon’s barrel by tying a bunch of iron rods around a log, welding them together, and binding the result with iron hoops, the point will get through. I’ll limit myself to one illustrative example:

The reason why Romans didn’t use screws in construction is not because they didn’t understand how a screw works. In fact they did use large “Archimedes' screws” as water pumps. Rather it’s because making screws to fasten wood would’ve required a skilled artisan carving them individually with a chisel or other hand tools, and that type of laborious detail work is just insanely impractical for making simple fasteners. Even nails were rare and expensive, partly because of the cost of iron and partly because of the labor involved in individually hammering each nail into shape. And forget about making machine screws to fit threaded metal holes or nuts; that level of precision would’ve been impossible at any price.

The machines used in the Industrial Revolution require the ability to manufacture very specific parts to very precise tolerances, and to do so cheaply and reliably. Making cylinders and linkages and springs and gears that will actually work in a complex machine without breaking can be done only with advanced, purpose-built tools, or in some cases (like the famous Antikythera mechanism) with the labor of master artisans which cannot be scaled up for mass manufacture. There were massive improvements in lathes, dies, and similar tools in the century or so before Watt’s steam engine, and without them the Industrial Revolution would have been impossible.

Some people believe that the Romans had the technology to start the Industrial Revolution because they’ve heard about a “Roman steam engine”. This is the aeolipile, a steam-powered spinning kettle which Hero of Alexandria described in the 1st century AD. This is an important scientific demonstration. However it is very very far from a machine that can perform any useful work, and incredibly crude compared to the engines which would power the Industrial Revolution 1700 years later. Hero’s machine produces very little power, and more importantly, it has no mechanism for transferring power to any useful purpose.

Here’s an illustration of Hero’s aeolipile:

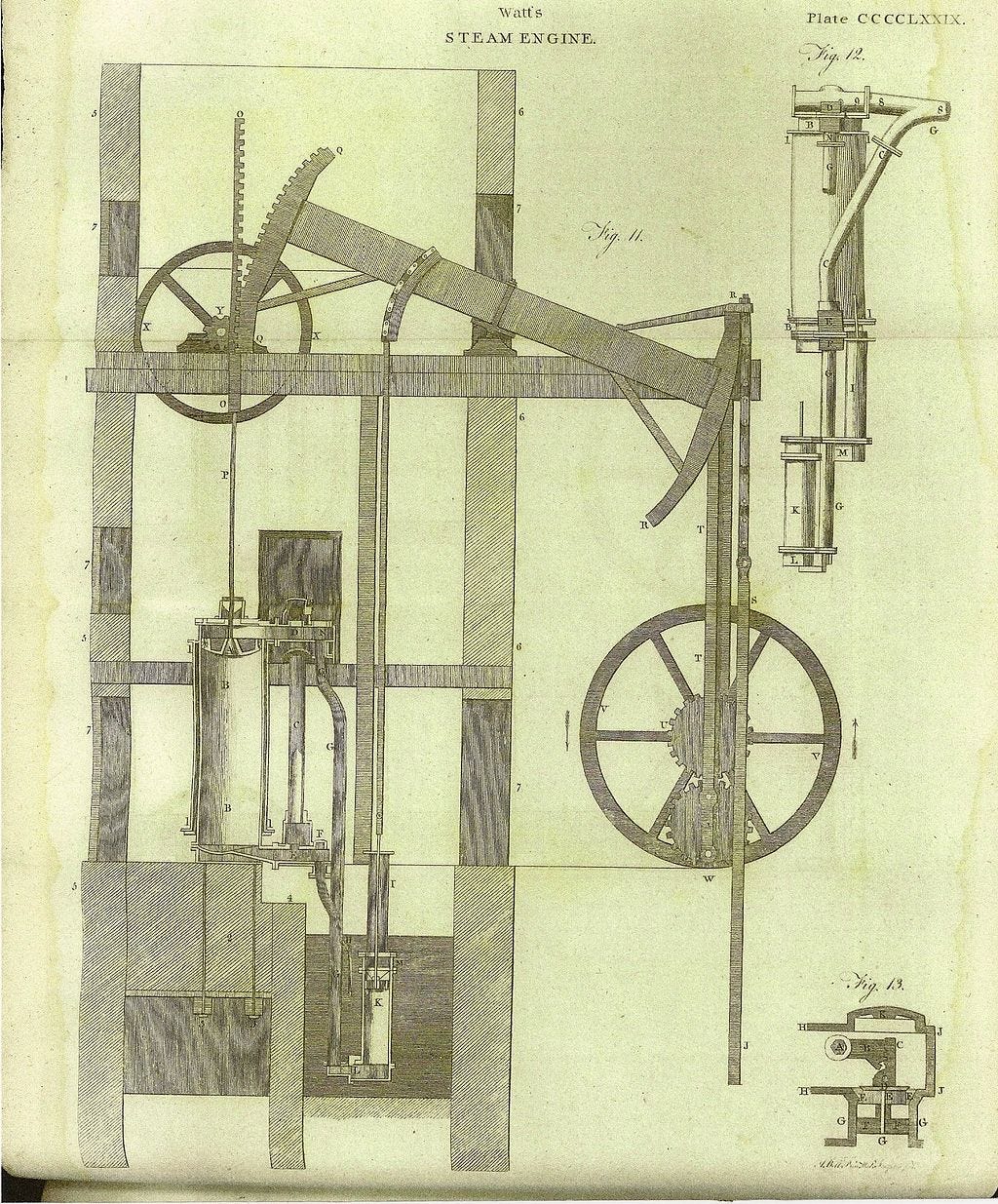

Compare this illustration of a Watt engine:

Clearly a civilization which sees the aeolipile as cutting-edge is not even close to manufacturing something like a Watt steam engine.

In fact Watt’s engine was only barely possible with the tools that existed in his time. After designing his improved steam engine on paper, Watt spent years trying to build it in reality, but could not get a functional prototype to work. The biggest problem was that the steam cylinders would leak too much. This was only solved in 1775, when the ironmaster John Wilkinson invented a new precision boring machine, originally for making better cannons but soon repurposed for Watt’s use as well.

Science. All civilizations have investigated natural phenomena. However there is a particular approach, which Joseph Needham describes as “the successful application of mathematical hypotheses to the systematic experimental investigation of natural phenomena”, that has been critical to industrial technology.2 This type of science is much rarer. Whatever Eratosthenes and Archimedes were doing, the Romans didn’t keep it up, and as far as I know it didn’t fully reemerge anywhere in the world until the 16th century.

The relationship between mathematical science and industrial technology is a giant topic which fills many books, so I’d better leave it at that for now.

Continent-Scale Markets. Mass manufacture is only economically viable at a truly giant scale. The vast, centralized ironworks of medieval China were only worthwhile where they were connected to the great network of canals which spanned the empire like today’s interstate highway system, just as the massive British textile factories were only worth building because their products could be exported to France and Egypt and Russia. Without such a market, the capital investments for industrialization will not pay off. The Romans traded and extracted goods throughout the Mediterranean world—they called it “Mare Nostrum”, or “Our Sea”. Modern society has its railroads and transoceanic cargo ships. The result of all this is that it can be profitable to build very expensive machines to manufacture low-margin commodities more cheaply.

Political Economy. The society must permit, if not support, the elites who organize and build out industrial infrastructure. (See also my essay on instruments of expansion.) Entrepreneur-driven industrial capitalism is of course the original and best-tested political-economic system for industrialization and industrial innovation. Other political economies have proved capable of transplanting preexisting industries, namely state champion industrial capitalism as practiced in much of East Asia today, and Soviet communism. However these other systems show little ability to establish genuinely new industries because they do not permit the gonzo social reengineering that comes with novel industrial breakthroughs. (I wrote more about this at New Industries Come From Crazy People.) As a result these systems wouldn’t be able to launch an Industrial Revolution of their own, even if they are functional industrial systems once the trail has been blazed. Other political-economic systems may well arise in the future, but as yet these are the only ones which have successfully industrialized.

The Industrial Revolution was executed by a society that was already based on entrepreneur-driven commercial capitalism, and so knew how to safely incorporate a new class of independent nouveau riche capitalists into its elite—we can see this same process happening with today’s software magnates. In contrast, Roman society was far too locked down, and its economy depended far too much on custom rather than a market-price system, to permit a massive industrial-capitalist buildout, or the rise of a new elite class that would come with it. I don’t believe the legend of Tiberius executing an inventor to protect the traditional economy, but it’s a legend no one could ever tell about Georgian England.3 In medieval China, “Capital accumulation in Chinese society there could indeed be, but the application of it in permanently productive industrial enterprises was constantly inhibited by the scholar-bureaucrats, as indeed was any other social action which might threaten their supremacy. Thus, the merchant guilds in China never achieved anything approaching the status and power of the merchant guilds of the city-states of European civilization.”4 To make durable family legacies, wealthy Roman merchants and manufacturers would try to buy estates and enter the dominant landlord-politician class, and wealthy Chinese merchants and manufacturers would try to educate their children and enter the dominant scholar-bureaucrat class… while wealthy English merchants and manufacturers would try to pass the family business down to their kids because entrepreneur-capitalists were already the dominant class.

Cheap iron. This one is a bit more speculative, and I’m not quite sure how to tell whether this was necessary for industrialization, or merely very useful. But it seems difficult to build huge quantities of massive iron machines if the iron itself is expensive and of irregular quality, as was the case throughout most of human history. The term “heavy industry” is not a metaphor.

China was the first civilization to mass-manufacture iron relatively cheaply, around the turn of the first millennium. Five or six hundred years later, Europe would match and then soon surpass this achievement during the early modern ramp-up of technological progress which eventually led to the Industrial Revolution. And of course Henry Bessemer’s 1856 invention of cheap, high-quality steel kicked off the so-called “Second Industrial Revolution” that inaugurated the most rapid century of technological advance in human history.

When people argue about “the cause” of the Industrial Revolution, this is an oversimplification, if an understandable one. For one thing, it’s a very complex topic, and it’s a pain in the ass to talk about the whole mess every time you want to make a narrow point about patents or whatever. But partly it’s because many people have a view of historical development that’s closer to destiny. Because we live in an industrial world, we assume that industrial development was natural and inevitable. We assume that there’s a sort of law of history that will eventually lead any human society to an industrial system that looks more or less like our own, with cars and power plants and cell phones and airplanes. And among people with the imagination to realize that the future will be different from the present, there’s an assumption that these same laws will continue to smoothly draw us up the slope of technological progress with the automatic inevitability of a ski lift.

I don’t think that’s true. Or maybe it’s true-ish on the scale of ten thousand years. But if you take the world as it existed in 1 AD, I don’t think historical laws guarantee an Industrial Revolution by 2000 AD. It seems to require more than just the slow accretion of physical technology which had been going on since the invention of the flint handaxe. There is a qualitative difference in European technological progress which starts around the time of the Scientific Revolution. The advent of mathematical science itself is not just a supercritical chain reaction that comes from sitting on top of a big pile of technology, as we can tell because Early Modern Europe’s rate of technological and scientific progress exceeded China’s even while its absolute level of technology and of physical knowledge was still behind. There was something else. That something else was rare, and probably very contingent.

If the wrong half dozen natural philosophers had died in infancy, then there probably wouldn’t have been a Scientific Revolution in Europe, and without it, no Industrial Revolution two centuries later. Maybe someone else would’ve industrialized in 2500, and then they’d look back on the Renaissance the way Westerners today look back at the Song dynasty. Or maybe if all the dice had come up just right, quantified experimental science could’ve gained ground in the Tang dynasty, and then if Song merchant guilds had somehow won the right power struggles and built out their power base, we can imagine a Chinese industrial revolution in like 1350. Or maybe the dice come up wrong over and over, and there’s still no industry by 6000 AD.5 None of these scenarios seems like an impossible outcome from the state of the world in 1 AD.

Follow Ben Landau-Taylor on Twitter: https://twitter.com/benlandautaylor

Jason Crawford pointed me to Flywheels of Progress, which I also recommend reading, where he makes a similar breakdown. His categories are a little different from mine, partly because he’s looking at a broader question in that essay, and partly because Jason takes a more teleological approach to this subject which puts less emphasis on regressions and collapses than I do. (This is our biggest longstanding difference of opinion.)

Joseph Needham, Science and Civilization in China, volume 7, part 2, page 2

We have two sources for this. One is Pliny’s Natural History, which says the story is “more widely spread than well authenticated”. The other is Petronius’s Satyricon, a work of satirical fiction, which puts the tale in the mouth of a foolish braggart who’s speaking absurdities. Additionally, the reasoning attributed to Tiberius doesn’t make any sense; he allegedly acted to preserve the value of gold and silver, which otherwise would have been replaced by the new supermaterial, but gold and silver are valuable because they are rare rather than because they are durable. (Modern retellings usually change the story so that he’s instead protecting traditional jobs, which matches our social scripts about new technology.). The properties of the alleged material seem unlikely, as well.

Joseph Needham, Science and Civilization in China, volume 7, part 2, page 9

This would require either appallingly bad luck, or else for there to be additional prerequisites to an industrial revolution that I haven’t yet identified and which are very hard to fulfill. I don’t think I’ve identified all the prerequisites so I can’t rule that out.

Bret Deveraux covered this question in significant technical detail, but I’ll summarize a bit: https://acoup.blog/2022/08/26/collections-why-no-roman-industrial-revolution/

Steam power has some circular dependencies. You need large amounts of coal to run a bunch of steam engines, but you also need steamships and steam locomotives to deliver the coal. This requires very sophisticated steam engines that are tricky to bootstrap into. Most pre-industrial cultures didn’t even use that much coal; wood and charcoal were the typical fuels. So how did the British bootstrap into steam power?

The earliest practical steam engines were uses to pump water from coal mines. But why would you mine for coal in the first place if you didn’t have steam power? In Britain’s case, it was because deforestation had already made them dependent on coal as a fuel source. Britain also had a sophisticated textile industry that allowed for more early applications of steam power. Another limiting factor for efficient steam power is the ability to construct metal cylinders capable of containing high levels of gas pressure, a problem that early modern Europe had spent centuries refining already in the form of cannon.

It’s possible that there could have been other development paths that led to steam; it’s hard to generalize from a sample size of one. Unlike industrialization, multiple cultures did all invent agriculture independently of each other, so we can compare them to find the common factors. But you can’t really do this with industrialization, which makes the question all the more interesting.

This is related to your section political economy but it seems like one of the essential ingredients for *the* Industrial Revolution is the Enlightenment, in particular the ideals of pursuing societal progress through the faculty of pure reason that was nurtured in the Enlightenment. If the French Revolution was the working out of those ideals in a social setting, the Industrial Revolution was a working out in a socio-economic setting.